Halal Assurance and Liability Quality System (HAL-Q)

Halal means things that Muslim can consume safely on both mind and body. Therefore, halal products must be without contamination and prohibited substances (Harom), that are designated by Islam that consuming them would harm one’s faith. Nowadays, the increasing complexity of raw material and manufacturing processes pose more risk of contamination of Harom, thus Muslim consumer are becoming more depending on safe halal standard. For this reason, quality halal certification has become one of the most important factors in building consumer’s trust. The halal standard includes safety systems such as SOP, GMP, HACCP etc. as its foundation. Seeing the importance, Halal Science Center integrated the safety standards with halal into Halal-GMP/HACCP which was then developed into HAL-Q.

Chulalongkorn University Halal Science Center has its main mission to improve the potential of national halal science and technology under the concept of “Religion rights, Science supports” with the aim to Improve “Thailand’s Identity of Halal Science” which is believed to lead to improvements on industrial level and of halal business and becoming world’s model of halal science institute development.

HAL-Q System Development Center is constructed together with the development of SILK (Shariah-compliant ICT Logistics Kontrol) which received the Top Innovation Award at World Halal Research Summit in 2012. SILK is the information technology system developed to serve in halal supply chain, logistics and traceability managements. The system is programmed to work hand in hand with HAL-Q to build competitive advantages for the industry installed with it.

HAL-Q =

H = Halal

A = Assurance

L = Liability

Q = Quality

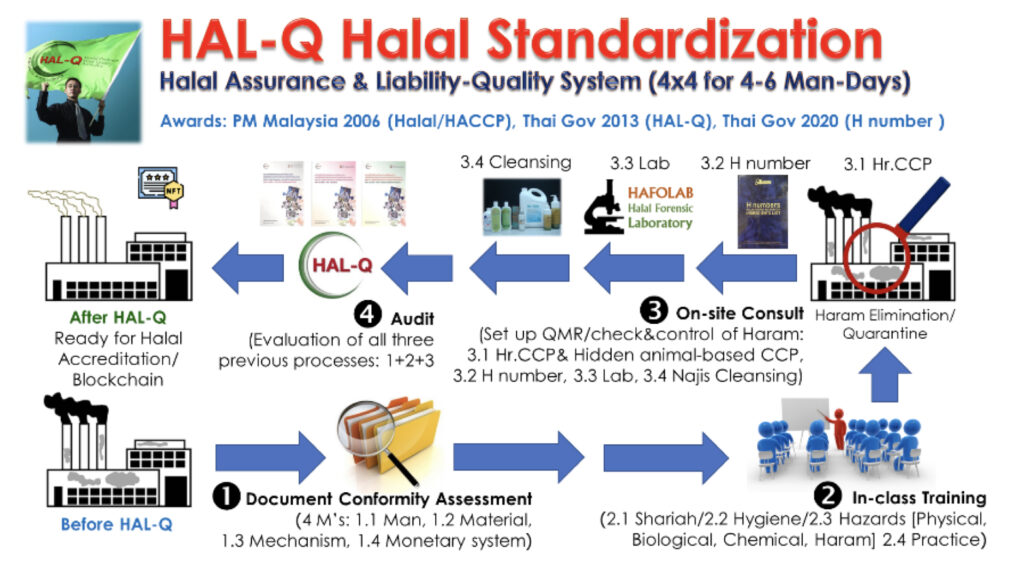

These programs cover fundamental Halal principles, guidelines for upholding Halal hygiene standards, and an introduction to the Halal-HACCP (Hazard Analysis and Critical Control Point) framework. Moreover, an auditor is tasked with the meticulous examination of the entire Halal food production process, rigorously assessing the potential for non-Halal contamination at various stages. Subsequently, the auditor identifies critical control points for non-Halal ingredients and appoints a quality management representative. Any materials or products suspected of non-compliance with Halal standards undergo a thorough examination in a Halal science laboratory. Furthermore, the production lines must undergo a thorough cleaning process with clay soap in accordance with Halal standards. Concluding this comprehensive evaluation, the auditor conducts a thorough assessment of the staff and evaluates the food manufacturing facility to determine if any improper handling practices have been rectified and meet Halal compliance standards. Following scientific validation and the successful resolution of identified deficiencies, the auditor confers HAL-Q certification upon the food plant. This certification attests to the effective implementation of the Halal management system in its food processing operations, rendering the facility eligible for accreditation by Islamic organizations (Figure 1).

History and Achievement of HAL-Q

1998 Dr. Winai Dahlan, a teacher of Faculty of Allied Health Sciences Chulalongkorn University, proposed the concept of safe halal food system placement for Thai Airways Kitchen in preparing meals for the 13th Asian Games.

1999 Dr. Winai Dahlan is associate with food institute wrote Halal-HACCP book for the first time.

2004 Halal Science Center applied Halal-HACCP system to the industrial sector and developed it to Halal-GMP/HACCP, and after that became HAL-Q

2006 HAL-Q received the Best Innovation in Halal Industry Award from the Prime Minister of Malaysia.

2009 HAL-Q received the Recognition Award for Halal Achievement from the Philippines.

2011 HAL-Q won the first prize at the World Halal Research Summit in Malaysia.

2012 Connected SILK with HAL-Q for the first time. HAL-Q became the system widely used in more than 250 factories covering more than 100 thousand of workers.